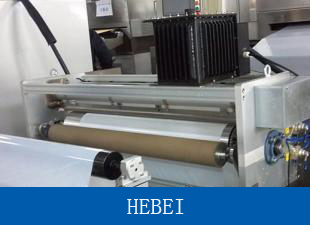

Aluminum Alloy roller is an economical, reliable and very effective, the surface does not need rubber coating or attach other insulators, so customers can greatly reduce the maintenance cost, but can also avoid the damage of the roller surface due to improper operation, can greatly improve work efficiency.

The use of spray coating technology on the roller surface with a layer of ceramic coating composed of polymer can greatly improve the uniformity of corona discharge compactness, while improving the roll surface corrosion resistance and hardness, which makes the effect of corona further improved, suitable for solar back plate, diaphragm and optical film industry and other occasions of high requirement of anti-breakdown.

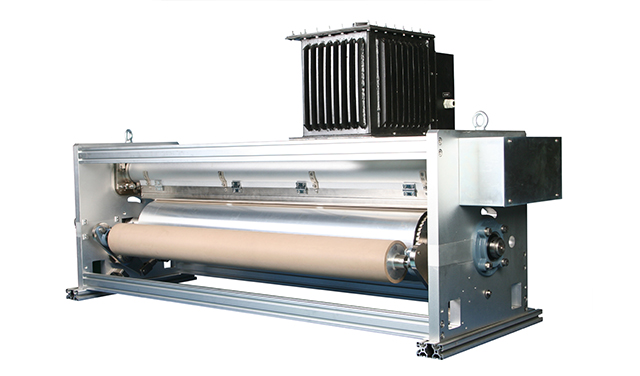

Output power: 2 ~ 30KW

Processing speed: 350m / min (maximum)

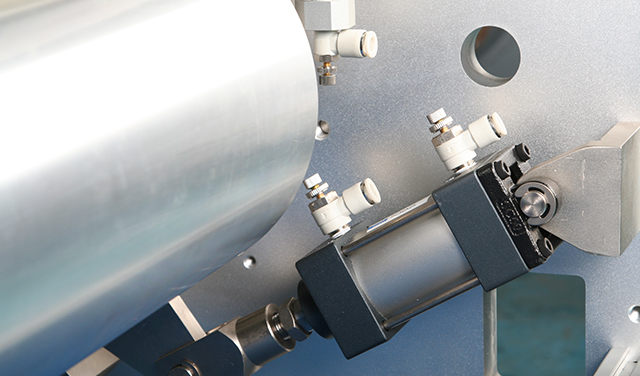

Opening and closing: Rotary opening and closing / up and down opening and closing / left and right opening and closing

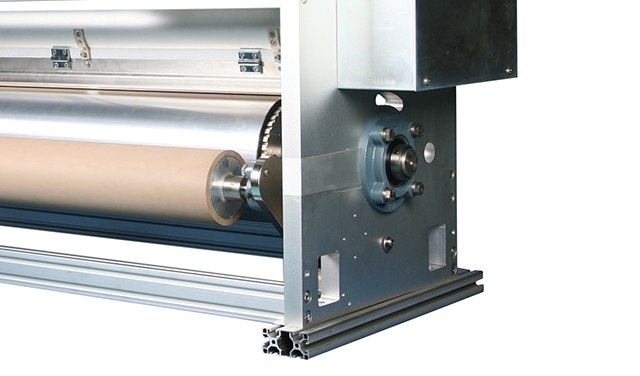

Processing roller: aluminum alloy roller / ceramic roller

Processing width: 600mm to 4000mm

Processing surface count: single / double

Electrode groups: 1 to 3 groups (depending on the power)

Cooling: air / water cooling (optional)

Transition roller: 1 to 2

Safety protection: speed protection, limit protection, leakage protection

Processing material: aluminum foil / copper foil / iron foil / PE (battery separator) / battery pole piece / paper (and all other materials)

Applicable equipment: coater / laminator / gravure printing machine / / Laminating machine / casting machine / film blowing machine / laminating machine and so on