2025-09-16

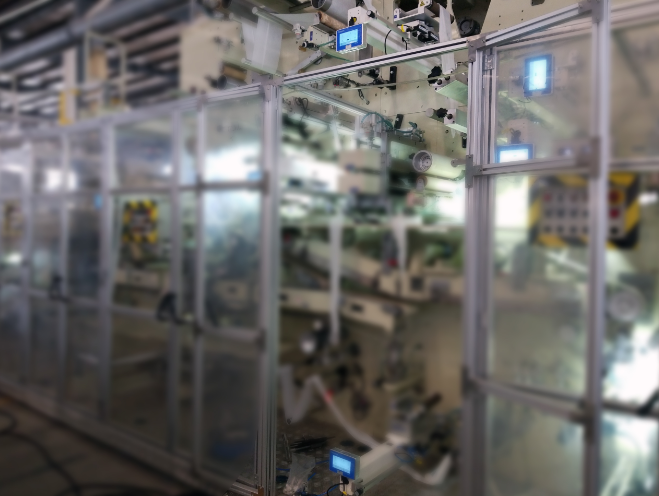

Techmach has been dedicating to offering comprehensive solution to sanitary product industry. Our main products include guiding control system, tension control system,corona treatment system, vision inspection system and thickness measurement system, widely used in equipment producing sanitary napkins, panty liners, baby diaper, adult diaper. With exquisite appearance, simple operation and customized service, which have been has been praised by the majority of users. Due to high cost-effective of our products, Techmach has been on the top of market for years.

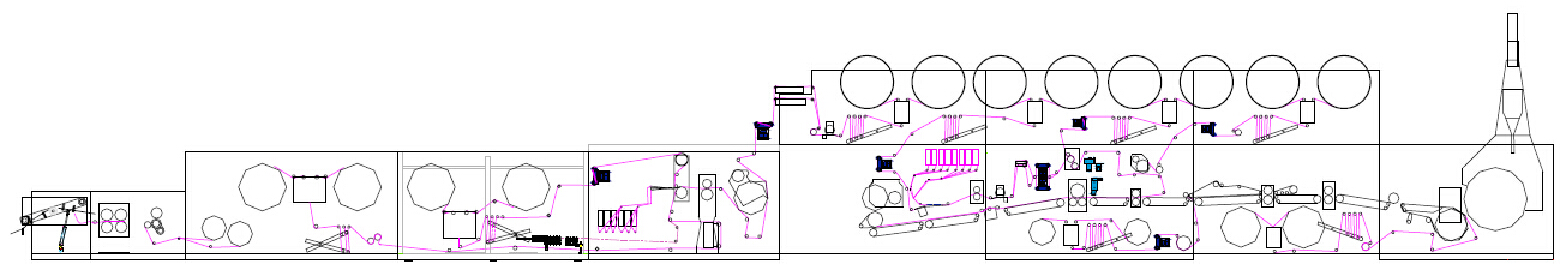

Principle of web guiding system:

Techmach web guiding system is to offer a solution for deviation of coiled material caused by material or equipment itself. It can track the position of coiled material and correct it in real time, which can guarantee and improve the quality and efficiency of production without manual intervention.

In order to meet the high-speed production requirement of the equipment, the number of web guiding systems in use will also increase, as an important part of sanitary product equipment. Web guiding system is mainly composed of controller, sensors, offset pivot guide frame and several other parts.

1. Web guiding controller:

Web guiding controller is the core part of web guiding system. Techmach web guiding controller has the features of easy operation, concise appearance and high precision.

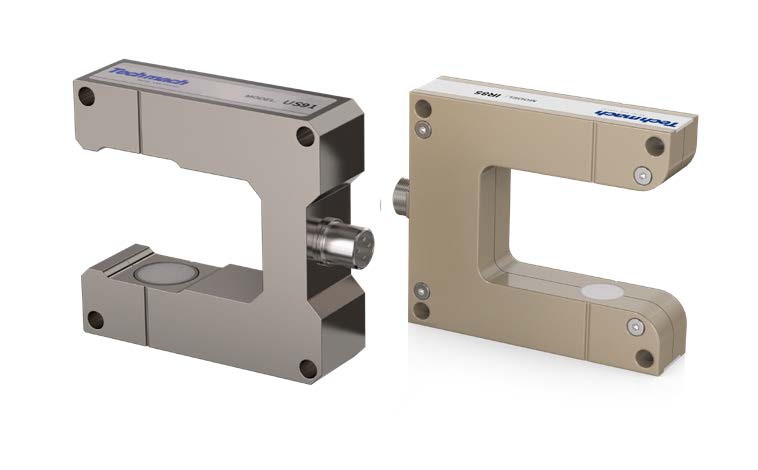

2. Web guiding sensor:

Infrared sensor is widely used in sanitary product industry. It has various advantages, such as high precision, quick response, adapted to diversified materials, small space occupation, etc.

3. Offset pivot guides frame:

Techmach offset pivot guides frame can meet the needs of all kinds of production lines in sanitary product industry. The small-width offset pivot guides frame is widely used in small-width production lines, such as production lines for sanitary napkin, pad, baby pants, etc. It is characterized by its easy installation and operation, exquisite appearance, etc. The wide-width offset pivot guides frame is widely used in production lines for pants, nursing pad, pet mattresses, etc. It is characterized by its smooth operation, high efficiency and reasonable price.

Tension control system:

With the rapid development of sanitary product industry, web tension control system also becomes indispensable in every production line. It can replace the traditional dancing roller tension control, and replace the old mechanical control with sophisticated electronic control. Techmach tension control system has been widely used in equipment producing lala pants, diapers, mattress, sanitary napkin and other sanitary products.

1. The main principle of the system:

Control and detect tension In each unit of unwinding part, and transfer the feed-back analog signal through the tension amplifier to the PLC and other control unit, so as to accurately control the tension of the material to meet the production process requirements of production line.

2. Composition and installation methods:

Tension transducer can be used in various ways. It can be used with signal amplifier, tension indicator, tension controller, etc. Its installation includes standard flange style and pillow mount installation.

3. Tension transducer:

It is used to measure the tension of the coil material. It adopts the foil strain gauge and Wheastone full bridge design. It has the advantages of high detection presicion, good linearity, high repeatability presicion, almost no lag, high overload coefficient, etc..

4. Tension controller:

It receives all kinds of signal, such as tension transducer signal, dancer roller signal, roller diameter position signal, ect. The input signal will be processed and transferred by a progressive PID to actuate different devices, including AC/DC Motors, pneumatic brake/clutch, powder brake/clutch, in order to regulate web tension.

5. Tension signal amplifier:

It receives signal from tension transducer, amplify it to a standard signal which proportional to web tension and transfer to PLC, computer and other kinds of tension controllers.

6. Tension indicator:

Tension indicator works together with tension transducer.It receives signal from transducer, amplify it to a standard signal which is proportional to tension, and transfer it to PLC, computer or other type of tension control equipment.

Vision inspection system:

Due to the mechanical error of the production equipment itself, raw materials, foreign body and production management and other reasons, it may cause defects and defective products in the production of sanitary products and their raw materials. Manual removal of waste is not only high cost, but also affects production efficiency. Techmach intelligent vision inspection system can detect impurities on the products accurately and comprehensively, for example, mosquitoes, hair, resin, stains, oil points, etc. It also can detect the quality of the product itself, like folds, leakage of cotton, and materials are not neat, etc. System operation is simple, full-featured, can be perfectly applied for sanitary towels, pads, diapers, mattresses and other sanitary product equipment, making it better to improve the market's reputation, reduce labor costs, improve product quality and production efficiency.

1. System composition and principle:

Broadly speaking, machine vision is the machine to replace the human eyes to make measurements and judgments.

Techmach Intelligent Vision Inspection System is comprised of high-speed CCD cameras, lenses, industrial LED light sources, encoders and integral racks and enclosures.

High-speed CCD camera capture illuminated, uniform brightness images, after synchronization, transfer into the computer or dedicated image processing module, and through the digital processing, according to the distribution of pixels and brightness, color and other information, to determine the deviations of size, shape, color etc.

Plasma spraying technology:

Techmach's plasma spraying technology is a newly developed technology in recent years. It is mainly used in the sanitary products industry for the functions of anti-sticking, non-slip, low friction and the like, and can effectively replace the traditional treatment methods of silicone, anti-sticking paper and talcum powder. By using spraying technologyn on the mechanical transmission parts of equipment for producing sanitary napkins, diapers, pull pants, mattresses and so on, can reduce operating costs, reduce downtime and labor costs.

1. Locations need to be sprayed:

Plasma spraying is mainly used on the guide roller, the transition wheel, driving wheel, etc. near the glue gun, it can not only be anti-sticking, but can also do low-friction treatment, such as anti-skid film drive roller and the clamping position of packaging machine.