2026-16-05

Segment Web Guiding System:

Techmach segment web guiding system is widely used in the textile production process of knitted fabric, warp knitted fabrics, tricot fabric and ect, play a web-guiding function. The system has high precision, good stability, less bias filling and so on.

Techmach segment web guiding system is a closed-loop control system composed of web guiding controller, infrared wide array sensor, and actuator to realize real-time fabric guiding. The system uses a full-width slat to increase the contact surface between slat and cloth to make sure that the system is highly efficient. There is sufficient gap between each slat to ensure that the machine is both high efficiency and less fabric abrasion in high-speed operation, in order to minimize bias filling.

Digital Printing Machine Cloth Feeding System:

Techmach digital printing machine cloth feeding system is used to feed fabric into a digital printing machine. The system consists of three parts, including A-type unwinding device, storage device and cloth-feeding device. This system can ensure continuous feeding and perfect tension control, to meet the printing equipment intermittent work requirements. The fabric is conveyed through the cloth-feeding device to the press-roller and finally comes to the digital inkjet process. This system can realize the storage, web guiding, and tension synchronously control to meet customer requirements for printing quality and accuracy.

Automatic Edge Cutting System:

The traditional mechanical cutting device can't achieve the precise cutting, resulting in the cut selvedge is too wide, wasting fabric, especially during the production of different width of the fabric when workers need to adjust cutter manually and the operation is very complicated.

Techmach automatic edge cutting system can automatically track the edge position of the fabric, so that the cutter is always in the position need to be cut, to achieve precision cutting, minimizing the cut selvedge, so as to achieve the purpose of reducing fabric loss . This system is equipped with Techmach high-precision wide array infrared sensor, to meet the production of different width of the fabric, no the need to manually adjust the cutter position.

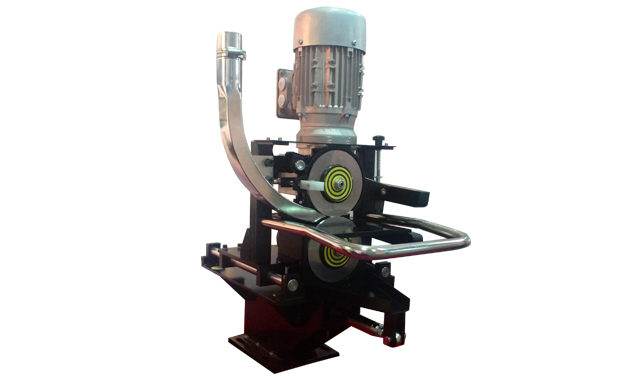

Tenter Guider:

For the stereotypes, whether the cloth edge can be fast and accurate put on the needle plate is the key factor in the production efficiency of the stereotypes, Techmach company launched the tenter guider can help customers solve this problem.

Techmach tenter guider consists of an actuator (built-in control board), an infrared sensor and an edge spreading device. Infrared sensor monitors the actual location of the selvage and transmits to the controller which compares the edge position and needle plate position difference and output control signal to the actuator which act accordingly to ensure the cloth edge can be quickly and accurately put on the needle board.

Tension Control System:

With the rapid development of the textile industry, the speed of various textile-related production lines is getting faster and faster. The accuracy of the tension control of the fabrics is getting higher and higher. The tension control system has become an indispensable product in every production line. Techmach's tension control system has been widely used in a variety of machines in the textile industry including monolayer stenter, printing machine, laminating machine, coating machine, mercerizing machine and ect.