2025-09-16

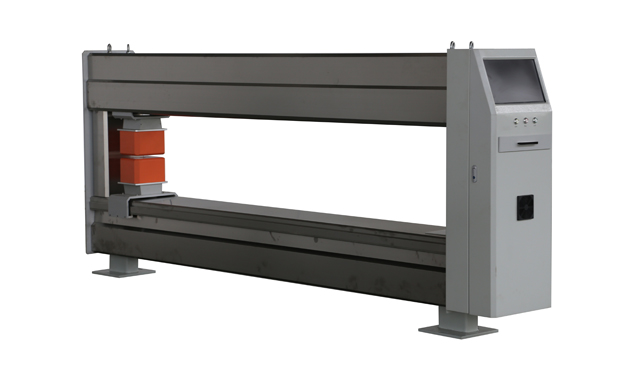

Working Principle:

The tenter guider consists of an actuator (built-in control board), an infrared sensor and an edge spreading device. Infrared sensor monitors the actual location of the selvage and transmits to the controller which compares the edge position and needle plate position difference and output control signal to the actuator which act accordingly to ensure the cloth edge can be quickly and accurately put on the needle board.

Porformance Characteristics:

● Analog control, to avoid the track back and forth jitter

● Electronic limit, to avoid damage to the track due to excessive stroke

● The left and right sides of the fabric are independently controlled

AC10 series tenter guider is clever-designed, compact, built-in control circuit board, brushless AC servo motor with high transmission efficiency planetary gear box, drive speed is up to 150mm/s.