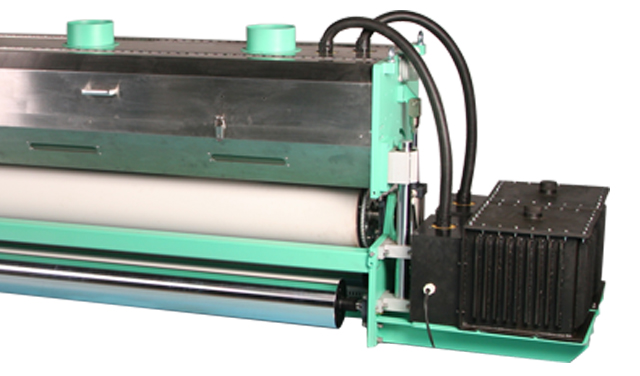

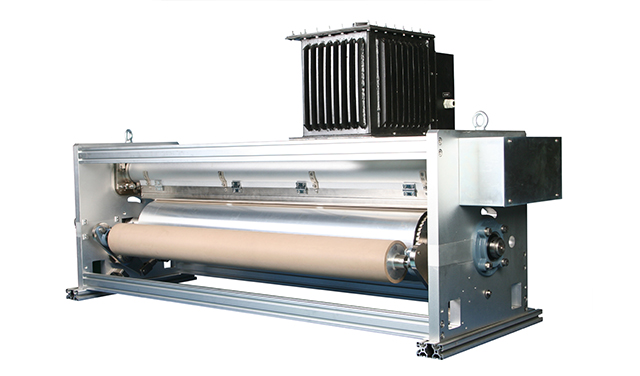

The surface of the rubber coated roller is made by the high temperature vulcanization process and the silicone rubber layer is pressed on the surface. Techmach adopts the imported high quality silicone material, which has the advantages of long service life, good insulation, puncture resistance, corrosion resistance and the like, can greatly improve the processing efficiency and service life of corona machine, while reducing customer maintenance costs.

The silica gel sleeve roller is made up of a layer of silica gel sleeve on the roller surface, and has the advantages of low investment compared with other rollers. It is economical corona equipment. Techmach used silicone sleeve all imported from the United States, with the advantages of high molecular density, good thickness uniformity and resistivity balance. The high molecular density extends service life, even thickness of the material makes operation more smoothly, the resistivity balance is fundamentally put an end to corona uneven phenomenon.

Processing material: BOPP, OPP, PET, PE, PEFT, paper and other non-conductive material

Output power: 2 ~ 30KW

Processing speed: 350m / min (maximum)

Opening and closing: Rotary opening and closing / up and down opening and closing / left and right opening and closing

Processing roller: vulcanizing rubber covered/ silica gel covered roller

Roller width: 600mm to 4000mm

Processing surface: Single / double

Electrode groups: 1 group to 3 groups (depending on the power)

Cooling: Cold / water cooling (optional)

Transition roller: 1 to 2

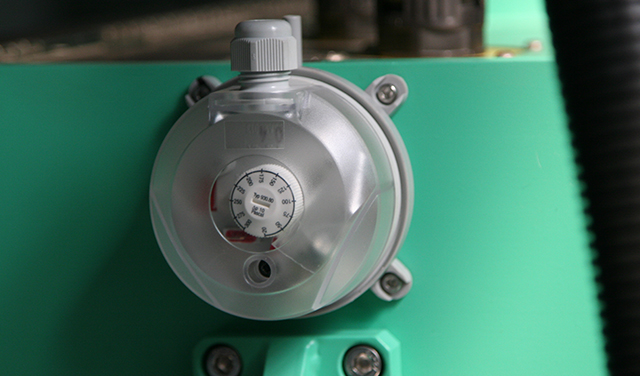

Safety protection: speed protection, limit protection, leakage protection

Suitable equipment: coating machine / composite machine / concave printing machine / wow printing plate / laminating machine / casting machine / film blowing machine / laminating machine etc.