During the production of lithium battery pole pieces, exposed foil, dark spots, bright spots, dross, scratches, damages and other defects may happen in the process of coating, rolling and so on. These defects will seriously affect the quality of the battery and service life. The electrode surface coating, marginal active substance shedding, the pole pieces satisfy the preset value or not, the defective product automatically collection, can be accomplished through the vision inspection system CCD camera module collecting the battery pole pieces image data, and processing module receives and processes image data.

Techmach vision inspection system can accurately detect all kinds of above defects in the production process of the pole piece, realize the on-line detection of double-sided defects in the pole piece coating production process and the pole-welding process, replace the traditional manual detection and improve production efficiency, and reduce customer quality complaints.

Schematic Diagram:

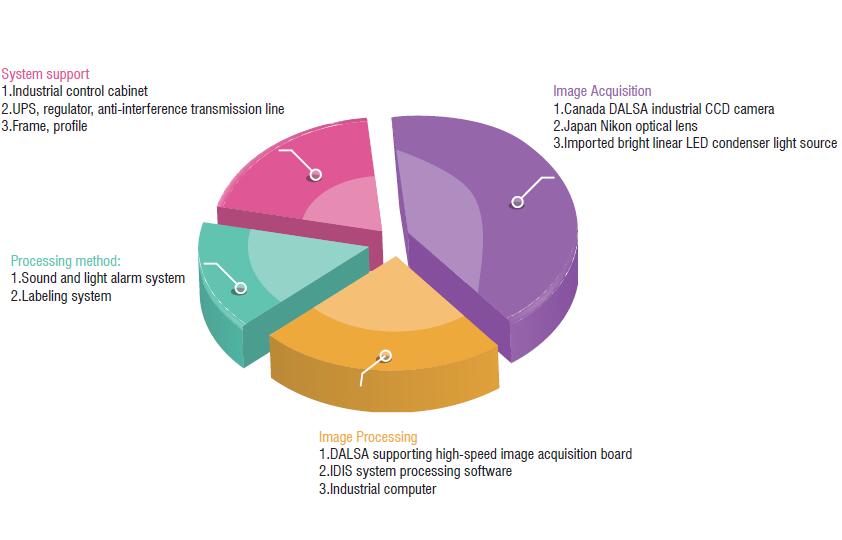

System Components:

Detection surface - single-sided or double-sided detection

Detection width - 1500mm or less (can be customized)

Defect detection accuracy - 0.1mm * 0.1mm