2026-16-05

1、Techmach web guiding system

In lithium battery industry, the battery pole piece of the continuous rolling production line, due to mechanical errors in the unit, guide roller deviation and vibration, pole piece tension fluctuation, and other causes, pole piece sometimes runs partially, which is extremely easy to cause damage in the process of rolling, seriously affecting the quality and economic benefits of the products. In the winding process, tower-type rolling phenomenon often occurs.

For the optical slitting machine, due to the material is expensive and thin, a little offset can cause material wrinkled and scrapped, will result in the waste of materials, reducing the economic benefits of customers.

Techmach web guiding system effectively overcome these problems, which is in the leading level of the industry. Techmach web guiding system detect the deviation through the sensor, compares the operation through the controller, and then sends the motion command to the actuator in a very short period, so as to ensure that the material can transmit through the designated line in the mechanical operation, the precision of web guiding can reach 0.1mm, completely meet the accuracy requirements of customers.

2、Techmach tension control system

In the production process of lithium coating and slitting, magnetic powder brake is often used in unwinding part, magnetic clutch or slip shaft is often used in rewinding part. The torque of the magnetic powder changes with the change of the current. At present, all controllers basically use the voltage-type output mode to control the magnetic powder. Voltage output type will lead to instability of the magnetic torque transmission, linear variation, tension fluctuations. Techmach's tension controller uses current output to make the torque transfer of magnetic powder more stable and reliable, and the tension fluctuation is greatly reduced. Coil in the coating process is more even, slitting more smoothly. Tension transducers currently on the market are basically the use of differential transformer to detect tension. Differential transformer has a fatal weakness of large zero drift and instable tension control. Techmach tension transducer adopts Wheatstone bridge metal foil strain gauge design, strong anti-interference ability, small zero drifting, wide detection range, fast response, good linearity.

Techmach tension control system can be directly docking inverter motor, servo motor to achieve automatic tension control. The coil can achieve stable tension control both at low speed and high speed. In addition, Techmach tension control system can also be high-speed non-stop volume change and new volume pre-drive and other functions, not only users can realize various operations and settings through controller's panel, but also can connected the controller to the PLC or computer, making the operation more convenient and faster, better meet the needs of customers.

3、Techmach corona treatment system

The application of corona treatment in the lithium battery industry can be traced back to 1990s, almost in sync with the development of lithium, but at that time the development of electronic power technology was unable to solve the problem of high frequency, so corona system failed to meet the requirements of the lithium industry development. In recent years,the development of electronic power, especially the development of high-frequency electronic technology, makes the development of the corona system is once again closely linked with the lithium battery industry. The applications of the corona system in lithium battery industry are divided into two parts, the first major category is Battery septum coating corona, the second category is the battery pole piece corona, after the corona treatment for the battery separator benefits mainly to improve the diaphragm absorbency of the battery solution, thereby enhancing the unit capacity of the battery, and For the pole piece, its main application is to improve the yield of the pole piece in the coating, reduce the foil and uneven phenomenon.

For the lithium battery production line, the corona processor is an effective device that can greatly improve the production efficiency and yield, greatly increasing the market competitiveness, it can be said that the corona processor is a heavy weapon in the lithium battery industry and is the decisive key to the victory.

Techmach corona controller adopts the latest international circuit design and first-class components, with the advantages of compact design, high conversion rate, stable performance and so on. Germany imported IGBT as the core of conversion, low heat, stable operation, bringing up to 87% conversion rate, more energy saving and enviroment protection. Using digital circuit, stable power output, convenient adjustment, built-in multiple security protection circuit, can effectively filter all kinds of harmonic pulse, adapt to more harsh electricity environment. Can be matched with ceramic electrodes, metal electrodes and other electrodes to meet the different needs of customers.

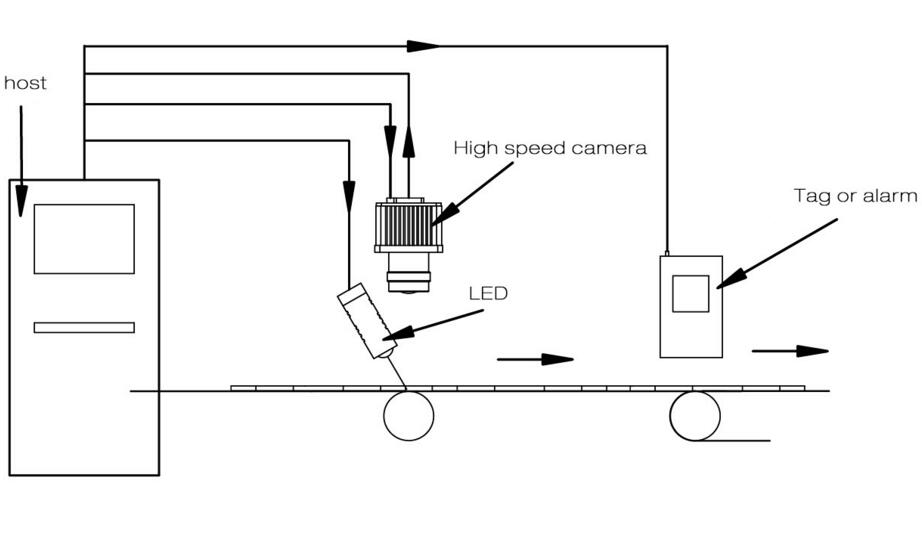

4、Techmach vision inspection system

During the production of lithium battery pole pieces, exposed foil, dark spots, bright spots, dross, scratches, damages and other defects may happen in the process of coating, rolling and so on. These defects will seriously affect the quality and the service life of the battery.

Techmach vision inspection system can accurately detect all kinds of above defects in the production process of the pole piece, realize the on-line detection of double-sided defects in the pole piece coating production process and the pole-ear welding process, replace the traditional manual detection and improve production efficiency, and reduce customer quality complaints.

Working principle diagram:

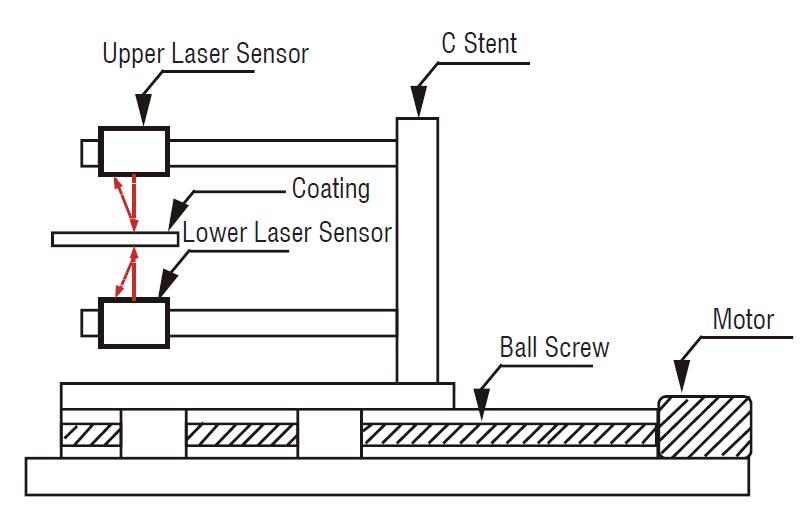

5、Techmach laser thickness measurement system

Techmach laser thickness measuring system is mainly composed of upper computer and control unit, thickness measuring unit and detector moving mechanism.At the same time, two laser displacement sensors are used to measure the position of the upper surface of the test object and the position of the lower surface, and the thickness of the measured body is calculated.

Suitable for measurement: continuous coating cold rolling, gap coating cold rolling, strip coating cold rolling.

Suitable products: positive pole piece, negative pole piece, copper foil, aluminum foil.