The composition and principle of Techmach vision inspection function:

Broadly speaking, vision inspection machine is the machine to replace the human eyes to make measurements and judgments.

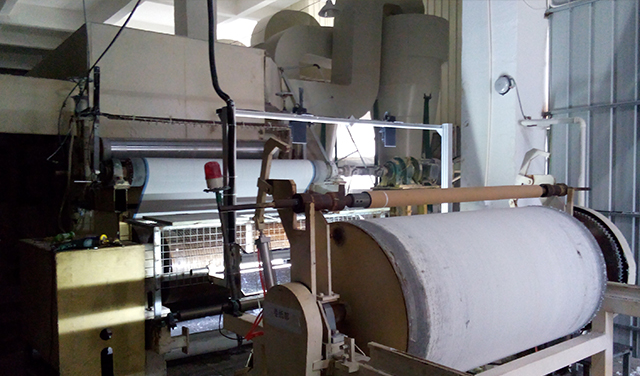

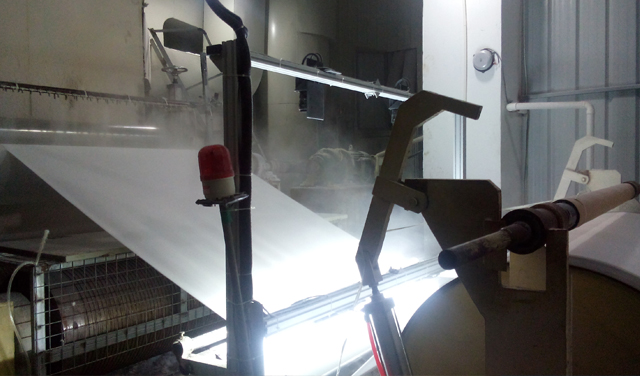

Techmach intelligent vision inspection system is comprised of high-speed CCD cameras, lenses, industrial LED light sources, encoders and complete machine racks and enclosures.

High-speed CCD camera capture illuminated, uniform brightness images, after synchronization, transfer into the computer or dedicated image processing module, and through the digital processing, according to the distribution of pixels and brightness, color and other information, to determine the deviations of size, shape, color etc.

The features of Techmach Vision Inspection System:

1, Techmach system is fast, easy to operate, easy to adjust the control parameters, reduce the requirements of the operator.

2, Classification, statistics and analysis of various defects in the production process, operator can clearly find the problem and direction of the generation of defects.

3, Replace the operator to complete the detection, saving manpower and resources.

4, Improve product qualification rate, reduce customer quality complaints.

Techmach vision inspection machine functions:

Defect position automatically labeled

Real-time defect detection alarm

Defect images automatically saved for easy retrieval queries

Techmach vision inspection machine performance parameters:

(1) It can detect black impurities larger than 0.5 square millimeters, gel impurities larger than 1.5 square millimeters and mixed impurities larger than 1 square millimeter on the surface of the product.

(2) Equipment to meet the host speed: design speed: 300 m / min. Normal speed: 300 / min.

(3) System accuracy: 0.5 square millimeters.

(4) Detection width: Through the camera combination to meet the different width up to 3000mm, metric design standards.

Detection Width: Through the camera combination to meet the different width up to 3000mm;

Detection speed: up to 300m / min speed;

Detection accuracy: 0.2mm ²